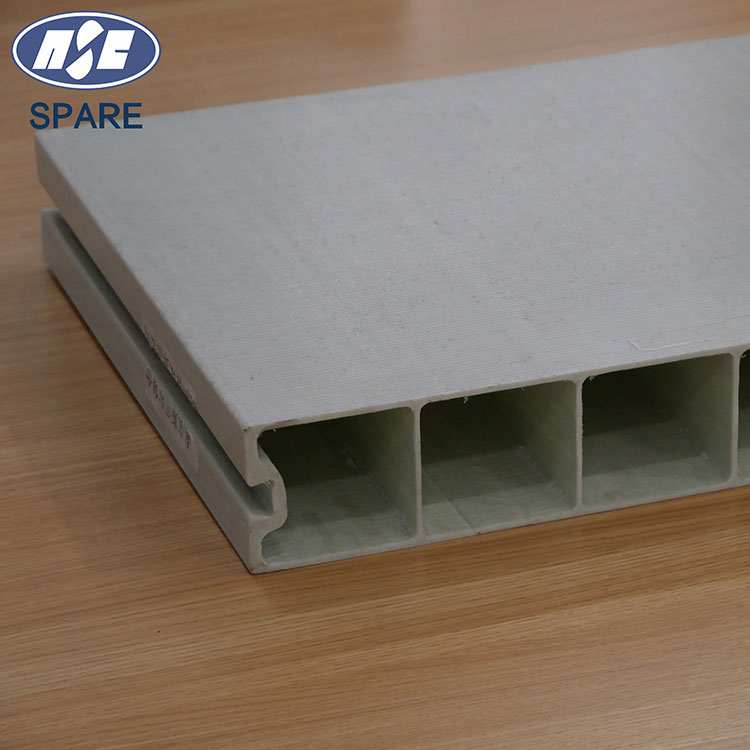

China Fiberglass Door Frame Manufacturer, Supplier, Factory

We are commitment to offer the competitive price ,outstanding products quality, as well as fast delivery for Fiberglass Door Frame,Fiberglass Doors and Windows,Fiberglass Windows,Fiberglass Door,Fiberglass Frame, We have ISO 9001 Certification and qualified this product or service .in excess of 16 years experiences in manufacturing and designing, so our goods featured with very best high-quality and aggressive rate. Welcome cooperation with us!

Fiberglass Door Frame, Profession, Devoting are always fundamental to our mission. We now have always been in line with serving customers, creating value management objectives and adhering to the sincerity, dedication, persistent management idea.

Hot Products

FRP Handrail

Ideal for durability, safety and environmental protection

Our Fiberglass (Fibre Reinforced Plastic) handrails are well-designed, durable and reliable marine engineering solutions. Using advanced materials and processes, our FRP handrails offer outstanding performance and a variety of benefits.FRP Decking

Discover the outstanding durability and versatility of our FRP (Fiber Reinforced Polymer) Decking, specially engineered to meet the rigorous demands of industrial, commercial, and coastal environments. Our FRP Decking offers superior strength, corrosion resistance, and low maintenance, making it the ideal solution for a wide range of applications, including boardwalks, bridges, and building structures, especially in harsh conditions.FRP Scraper

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Scraper is customized product.FRP Optical Cable Core Fiberglass Rod

The FRP Optical Cable Core Fiberglass Rod is a high-strength, lightweight composite material specifically designed for use within optical cable structures. It delivers excellent tensile strength, corrosion resistance, and durability, making it suitable for challenging environments and ensuring the longevity and stability of optical cables.FRP Covers

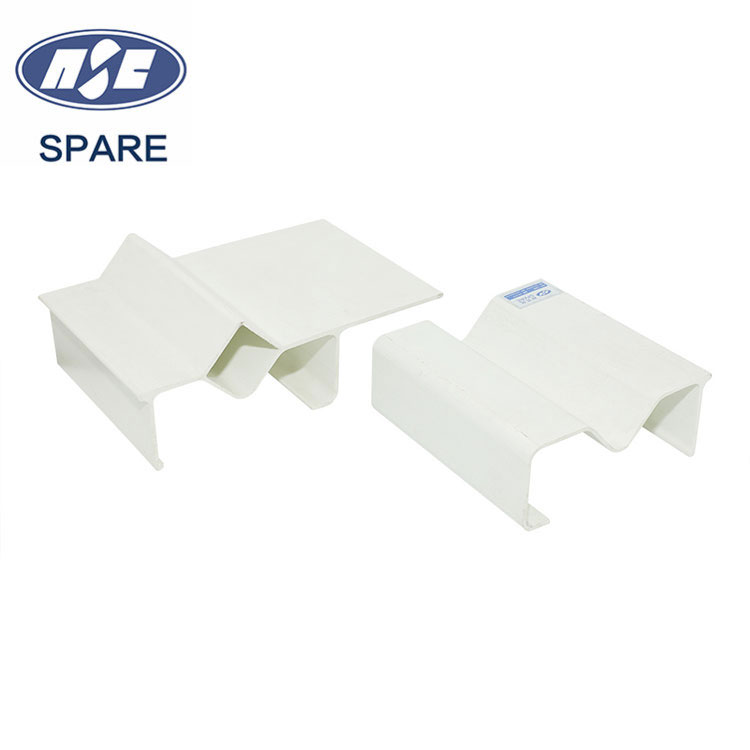

FRP Covers products are durable covers made from high strength fibre reinforced plastic (FRP). They are used in a wide range of applications in the construction, industrial, transport and infrastructure sectors and are designed to protect and cover critical equipment, pipelines, access routes, etc., thus providing a safe, durable and aesthetically pleasing solution.FRP Corrugated Board

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Corrugated Board is customized product.