China Fiberglass Handrail Manufacturer, Supplier, Factory

With our rich working experience and thoughtful companies, we have now been recognized as being a trustworthy supplier for a lot of global potential buyers for Fiberglass Handrail,Fiberglass Handrails and Fences,Fiberglass Fence,Fiberglass Guardrail,FRP Handrails, We wholeheartedly welcome consumers all over the entire world appear to go to our manufacturing unit and have a win-win cooperation with us!

Fiberglass Handrail, All our staffs believe that: Quality builds today and service creates future. We know that good quality and the best service are the only way for us to achieve our customers and to achieve ourselves too. We welcome customers all over the word to contact us for future business relationships. Our items are the best. Once Selected, Perfect Forever!

Hot Products

T-Type Fiberglass Pultruded Grating

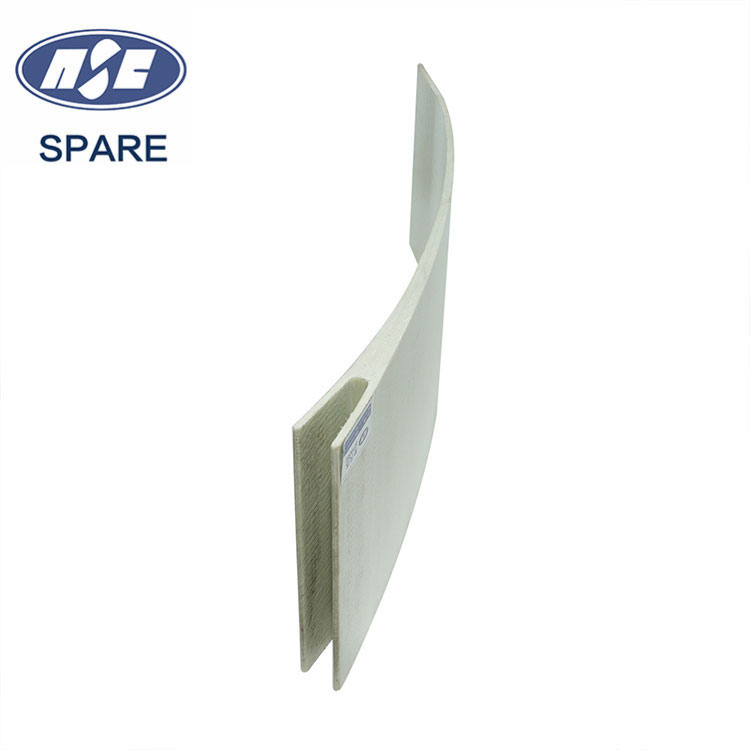

T-Type Fiberglass Pultruded Grating is a plate with gaps made by using pultruded "I" and "T" shaped profiles as load-bearing bars, solid pipes or rods as connecting rods, and a certain assembly process.FRP Corrugated Board

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Corrugated Board is customized product.FRP Power Safety Net

FRP power safety net is a kind of power equipment safety protection net made of FRP material, which is used to protect the safety of power equipment and personnel.FRP 50 Square Tube Accessories

FRP 50 square tube accessories refer to accessories used to connect, fix and support FRP 50 square tubes, usually made of FRP materials.FRP Bowler Hat Profile

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Bowler Hat Profile is customized product.FRP Window Frame Profiles

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Window Frame Profiles is customized product.