China GFRP Cable Bracket Manufacturer, Supplier, Factory

"Based on domestic market and expand abroad business" is our progress strategy for GFRP Cable Bracket,GRP Cable Bracket, We're going to provide high-quality merchandise and excellent products and services at competitive costs. Start benefiting from our comprehensive products and services by contacting us today.

GFRP Cable Bracket, With nearly 30 years' experience in business, we have been confident in superior service, quality and delivery. We warmly welcome customers from all over the world to cooperate with our company for common development.

Hot Products

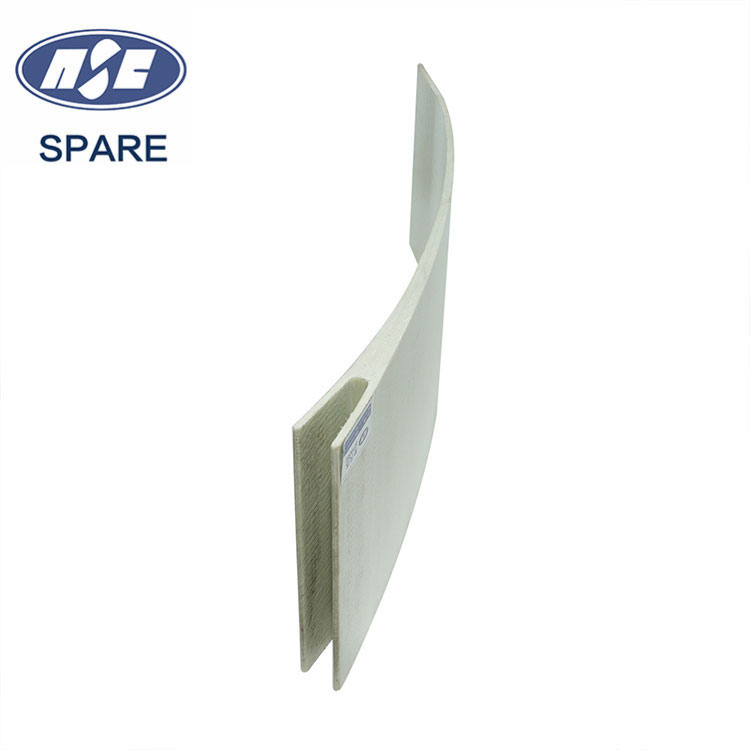

FRP Skirting Board

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Skirting Board is customized product.FRP 50 Square Tube Accessories

FRP 50 square tube accessories refer to accessories used to connect, fix and support FRP 50 square tubes, usually made of FRP materials.FRP Bowler Hat Profile

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Bowler Hat Profile is customized product.FRP D Profile

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP D Profile is customized product.Fiberglass Guardrail Handrail

Fiberglass guardrail handrails are a kind of handrail material made of fiberglass and resin. They are often used in the design of guardrail handrails in stairs, corridors, balconies and other places.FRP Decking

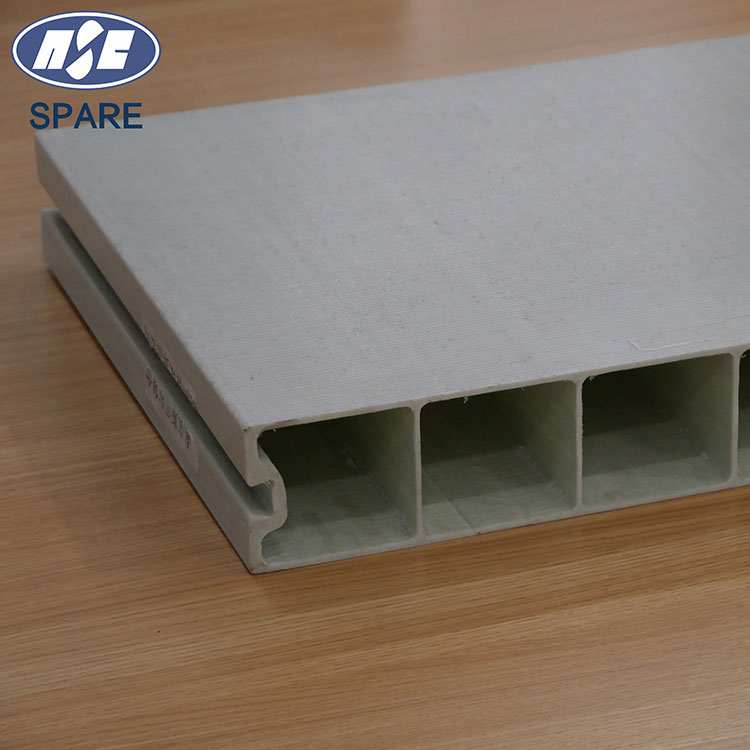

Discover the outstanding durability and versatility of our FRP (Fiber Reinforced Polymer) Decking, specially engineered to meet the rigorous demands of industrial, commercial, and coastal environments. Our FRP Decking offers superior strength, corrosion resistance, and low maintenance, making it the ideal solution for a wide range of applications, including boardwalks, bridges, and building structures, especially in harsh conditions.