China Molded Fiberglass Grating Manufacturer, Supplier, Factory

The incredibly rich projects administration experiences and a person to 1 service model make the substantial importance of organization communication and our easy understanding of your expectations for Molded Fiberglass Grating,Ballistic and Storm Panel,Fabricated Structure,Concrete Bridge Deck Reinforcement,Strengthening Strip, We welcome you to inquire us by get in touch with or mail and hope to create a successful and cooperative partnership.

Molded Fiberglass Grating, Faced with the vitality of the global wave of economic integration, we are confident with our high-quality products and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.

Hot Products

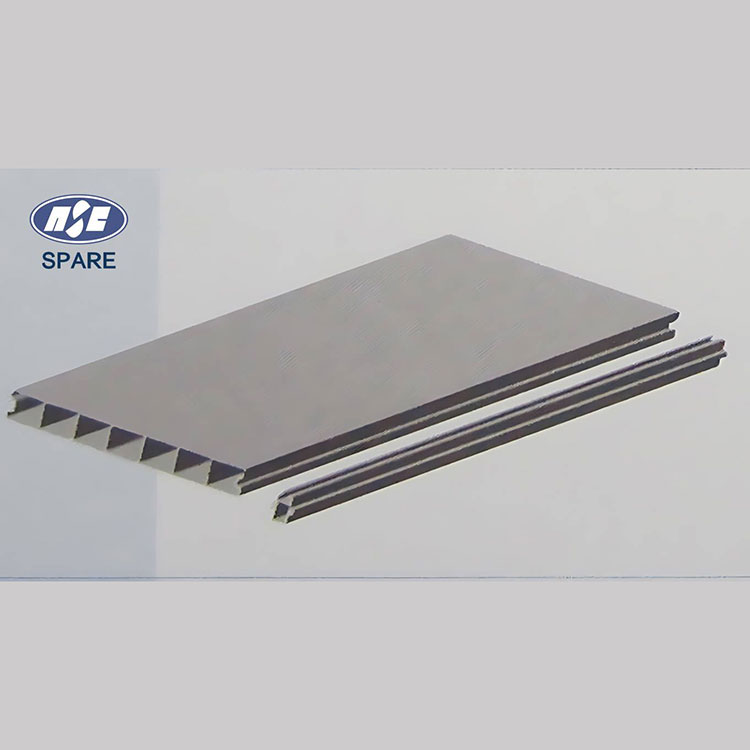

T-Type Fiberglass Pultruded Grating

T-Type Fiberglass Pultruded Grating is a plate with gaps made by using pultruded "I" and "T" shaped profiles as load-bearing bars, solid pipes or rods as connecting rods, and a certain assembly process.FRP Toothed Tube

FRP Toothed Tube is a high-performance composite material tube that incorporates a specific toothed shape on its inner and outer surfaces to enhance structural rigidity and connection strength. This material combines lightweight, high strength, and corrosion resistance, making it suitable for use in automation machinery, automotive manufacturing, and construction engineering among other fields.FRP Lower Pallet Rack

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Lower Pallet Rack is customized product.Composite Cooling Tower

The composite cooling tower, a large-scale heat exchanger, primarily serves power plants and manufacturing plants by cooling water. It cools essential equipment during daily operations. Its main structure includes square tubes, rectangular tubes, angle steel, grooves, I-beams, decks, flat bars, etc. Special shapes like handrails and kick plates are used on the guardrails. Blades, crucial components of cooling tower fans, generate airflow, facilitating heat exchange between circulating water and ambient air for cooling. Nanjing SPARE cooling towers made of extruded GFRP, the following standards are followed:

GB/T7190.2-2017 Mechanical Ventilation Cooling Towers Part 2: Large Open Cooling Towers.

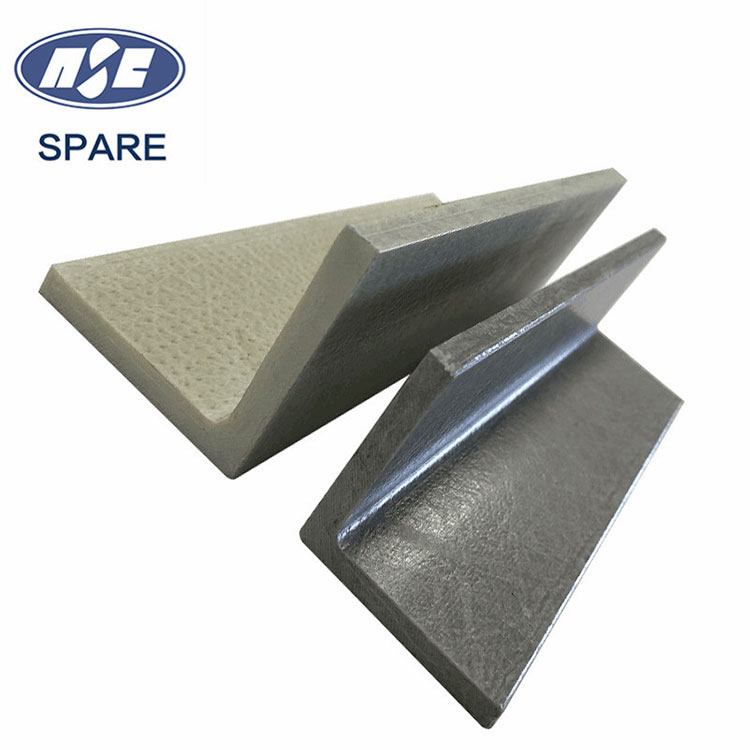

GB/T 31539-2015 Structural Fibre Reinforced Composite Profile Extrusions.FRP Bowler Hat Profile

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Bowler Hat Profile is customized product.FRP Cable Bracket

FRP cable bracket is a device used to support and fix cables. It is made of fiberglass material and has good corrosion resistance and mechanical strength.