- Custom Pultrusion Shapes

- FRP Standard Profile

- Vehicle Composite Profiles

- FRP Bridge Components

- FRP Ladder Rail Profiles

- FRP Tool Handles

- FRP Epoxy Pultruded Profiles

- Fiber-Reinforced Connectors

- FRP Covers

- Composite Cooling Tower

- FRP Decking Solutions

- FRP Grating

- Fiberglass Handrail and Fencing

- Fiberglass Windows and Doors Profiles

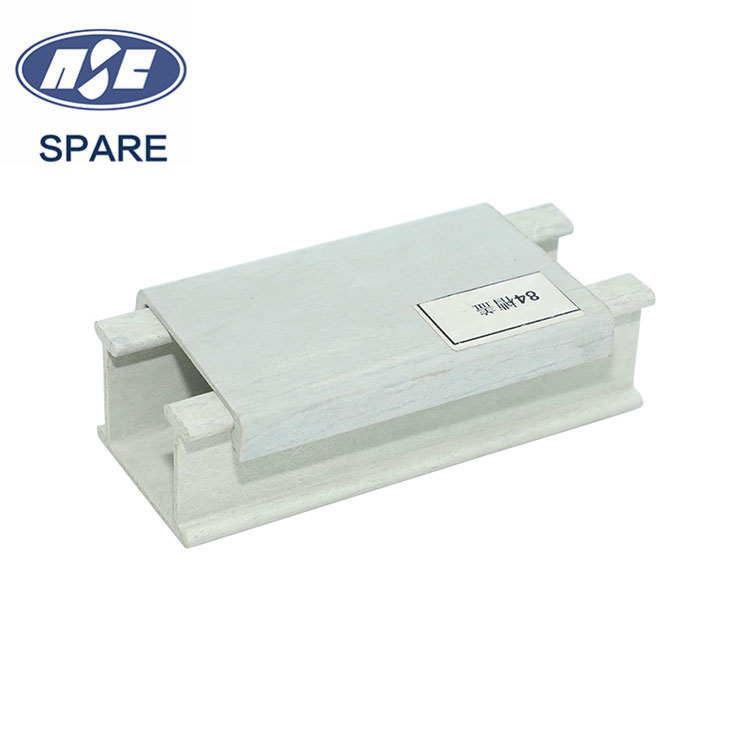

- Structural Reinforcements and Profiles

- Composite Frames for Solar Panels

- FRP Cable Tray

FRP Sheet Piling

FRP sheet piling is an efficient and environmentally friendly alternative to steel sheet piling in marine structures, flood walls,and seepage barriers. It's the strongest, most durable composite sheet piling profile available and often specified for bulkheads in areas that require heavy loading support.

Send Inquiry

Superior Corrosion Resistance

FRP (Fiber Reinforced Polymer) composite sheet piling offers exceptional corrosion resistance compared to traditional materials. Seawater, with its high salt content, causes traditional steel seawalls to rust, necessitating frequent maintenance and protective coatings. FRP, with its inherent corrosion-resistant properties, eliminates the need for additional protective layers, significantly reducing maintenance costs and frequency. Coastal regions in the United States that have adopted FRP sheet piling have successfully lowered maintenance expenses and extended the lifespan of their seawalls.

Lightweight and Easy Installation

FRP sheet piling is approximately one-fourth the weight of traditional steel, making it easier and more economical to transport and install. In large seawall construction projects, using FRP sheet piling has significantly shortened construction time and reduced costs. For instance, an Australian seawall restoration project that replaced concrete sheet piling with FRP experienced reduced on-site construction time and eliminated the need for heavy lifting equipment, resulting in substantial labor and equipment cost savings.

UV and Chemical Resistance

FRP composite materials provide excellent resistance to UV radiation and chemical corrosion, maintaining their performance in harsh environments. This makes FRP ideal for seawalls exposed to prolonged sunlight and chemical agents. Case studies, such as those involving seawalls near petrochemical plants, demonstrate that FRP sheet piling outperforms traditional materials in durability, requiring fewer replacements and repairs.

Cost Efficiency Over the Long Term

While the initial cost of FRP composite sheet piling may be higher than traditional materials, it proves to be more economical over the lifecycle of the seawall. For example, a seawall project in a Canadian port revealed that despite higher upfront costs, overall expenses were approximately 30% lower with FRP compared to traditional steel seawalls due to reduced maintenance and longer replacement intervals.

Understanding the FRP Pultrusion Process

We are manufactures, engineers, designers and fabricators.

Benefits of FRP

Framework stability

Superior corrosion resistance

lightweight

Easy to install

High Strength

customisable

Durability

Non-Conductive

Non-Magnetic

Thermal Stability

Low Maintenance Costs

Low Thermal Conductivity

Qualification Certificate