China Composite material sheet pile Manufacturer, Supplier, Factory

It is a great way to further improve our items and repair. Our mission would be to develop resourceful items to clients with a superior encounter for Composite material sheet pile,Fiberglass sheet pile,Composite sheet pile,Fiberglass water blocking plate,Fiberglass fence, Our hugely specialized process eliminates the component failure and offers our customers unvarying high quality, allowing us to control cost, plan capacity and maintain consistent on time delivery.

Composite material sheet pile, During in 11 years, We have now participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

Hot Products

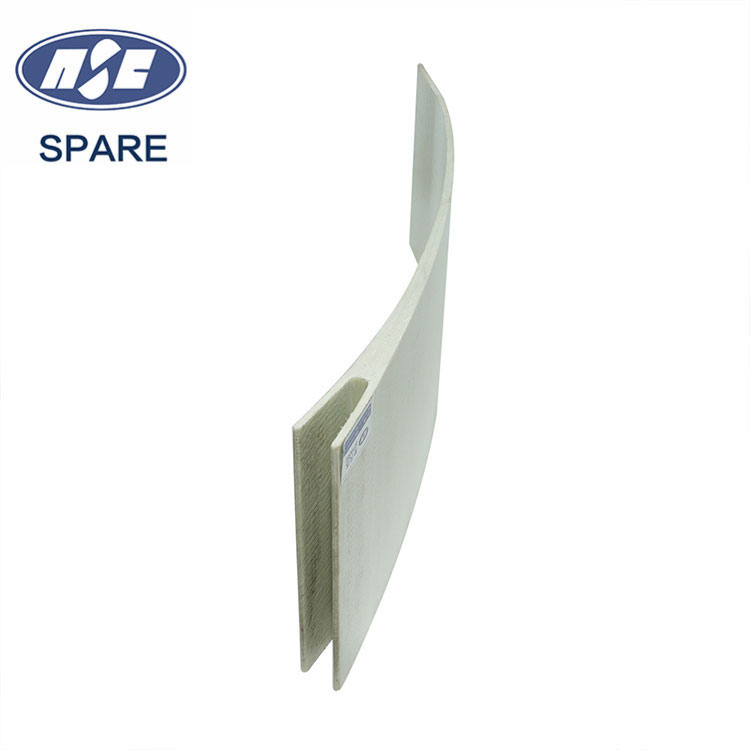

FRP Skirting Board

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Skirting Board is customized product.FRP Fish Lower Lip

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Fish Lower Lip is customized product.FRP Toothed Tube

FRP Toothed Tube is a high-performance composite material tube that incorporates a specific toothed shape on its inner and outer surfaces to enhance structural rigidity and connection strength. This material combines lightweight, high strength, and corrosion resistance, making it suitable for use in automation machinery, automotive manufacturing, and construction engineering among other fields.FRP Cable Bracket

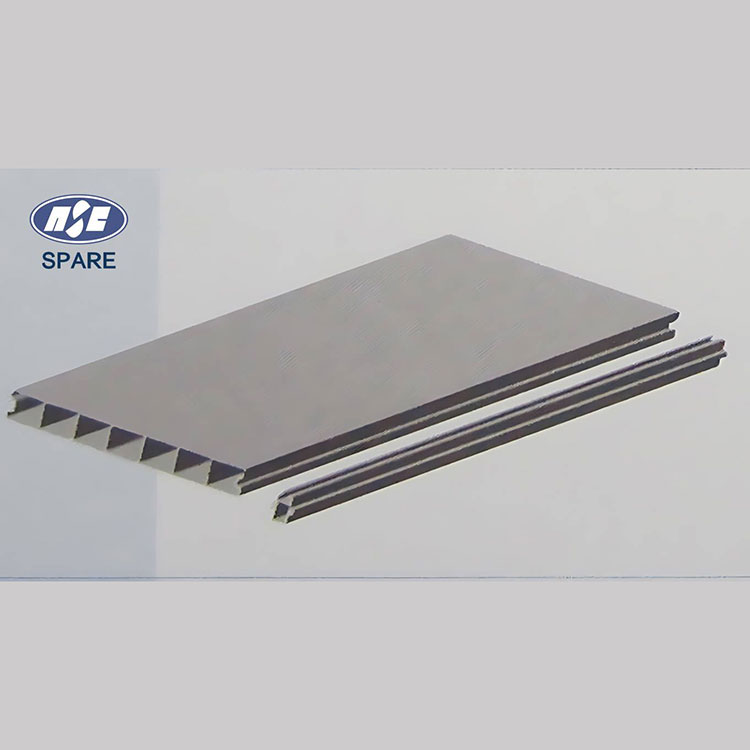

FRP cable bracket is a device used to support and fix cables. It is made of fiberglass material and has good corrosion resistance and mechanical strength.Hollow Decking

Our FRP Hollow Decking, made from Fiber Reinforced Polymer (FRP), was successfully used on Thailand's Rama VIII Bridge. These GFRP pultruded hollow web panels reduce wind resistance, lower maintenance costs, and enhance aesthetic appeal. Installed after rigorous field loading tests, our decking offers superior quality and reliability for any project.Fiberglass Handrail

Fiberglass handrails are handrails made of fiberglass reinforced plastic (glass fiber reinforced plastic). Its characteristics include corrosion resistance, wear resistance, lightweight and other advantages.