China Custom-Made FRP T Profiles Manufacturer, Supplier, Factory

abide by the contract, conforms into the market requirement, joins in the market competition by its good quality also as provides a lot more comprehensive and great company for purchasers to let them turn into huge winner. The pursue from the firm, would be the clients' gratification for Custom-Made FRP T Profiles,FRP Class T Profiles,Custom FRP Profiles,Fiberglass Reinforced Plastic Class T,Customized FRP T Profiles, Our firm is functioning with the procedure principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we could have a pleasant romantic relationship with businessman from all around the environment.

Custom-Made FRP T Profiles, We insist on "Quality First, Reputation First and Customer First". We are committed to providing high-quality items and good after-sales services. Up to now, our solutions have been exported to more than 60 countries and areas around the world, such as America, Australia and Europe. We enjoy a high reputation at home and abroad. Always persisting in the principle of "Credit, Customer and Quality", we expect cooperation with people in all walks of life for mutual benefits.

Hot Products

FRP Toothed Tube

FRP Toothed Tube is a high-performance composite material tube that incorporates a specific toothed shape on its inner and outer surfaces to enhance structural rigidity and connection strength. This material combines lightweight, high strength, and corrosion resistance, making it suitable for use in automation machinery, automotive manufacturing, and construction engineering among other fields.Fiber-reinforced Composite Rebar

Fiber-reinforced composite rebar is a kind of composite material made of polymer resin as the matrix and glass fiber, basalt fiber or carbon fiber as the reinforcement.FRP Decking

Discover the outstanding durability and versatility of our FRP (Fiber Reinforced Polymer) Decking, specially engineered to meet the rigorous demands of industrial, commercial, and coastal environments. Our FRP Decking offers superior strength, corrosion resistance, and low maintenance, making it the ideal solution for a wide range of applications, including boardwalks, bridges, and building structures, especially in harsh conditions.FRP Fish Upper Lip

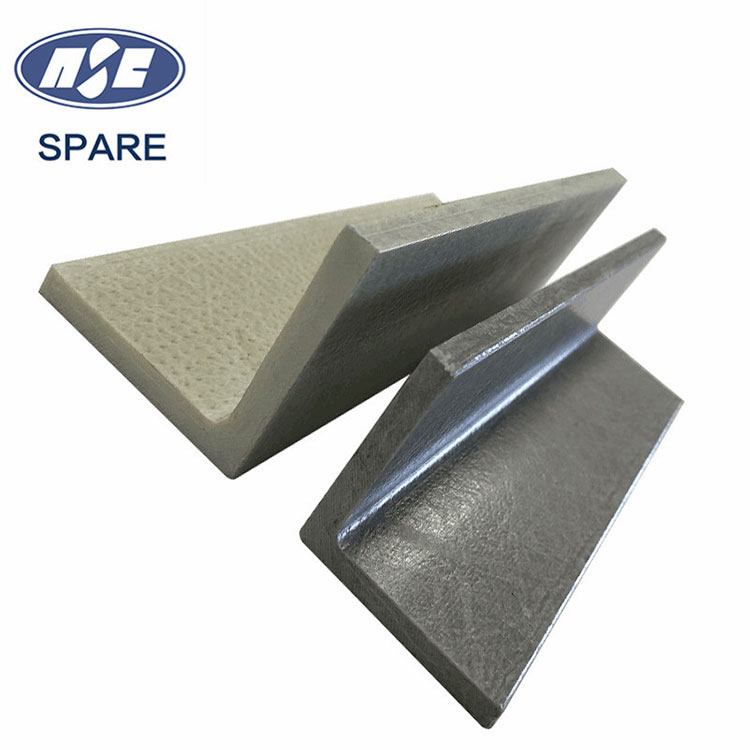

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Fish Upper Lip is customized product.FRP Corrugated Board

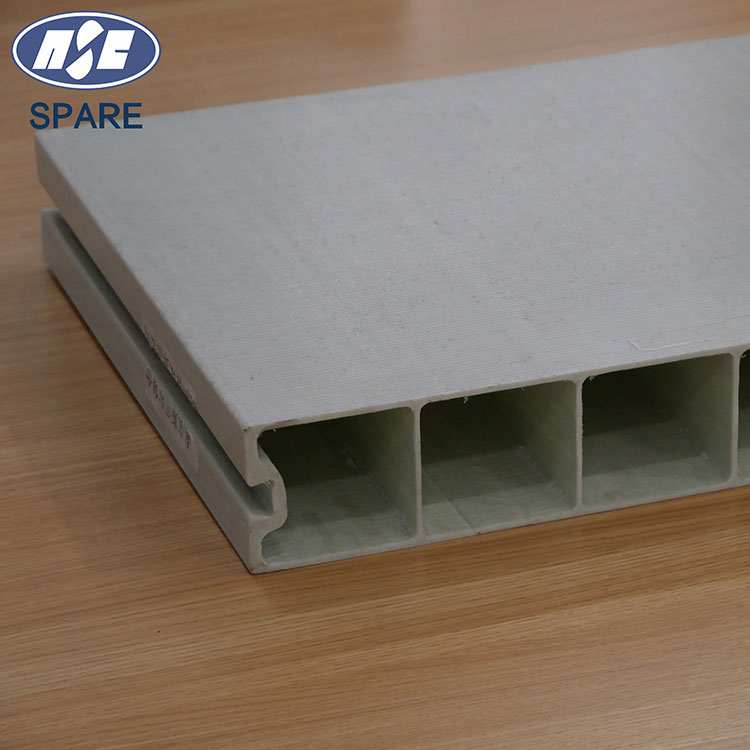

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Corrugated Board is customized product.Double Sided Flat Grille

The double sided flat grille is a molded grating bonded with a hand-laid FRP plate to form a structural plate with one or both sides closed.