China Fiber Reinforced Polymer Manufacturer, Supplier, Factory

Just about every member from our large efficiency income crew values customers' wants and enterprise communication for Fiber Reinforced Polymer,FRP Sheet,FRP Plate,Pultruded Stair Treads,Composites Materials, The concept of our organization is "Sincerity, Speed, Provider, and Satisfaction". We are going to follow this concept and earn more and more customers' satisfaction.

Fiber Reinforced Polymer, Profession, Devoting are always fundamental to our mission. We now have always been in line with serving customers, creating value management objectives and adhering to the sincerity, dedication, persistent management idea.

Hot Products

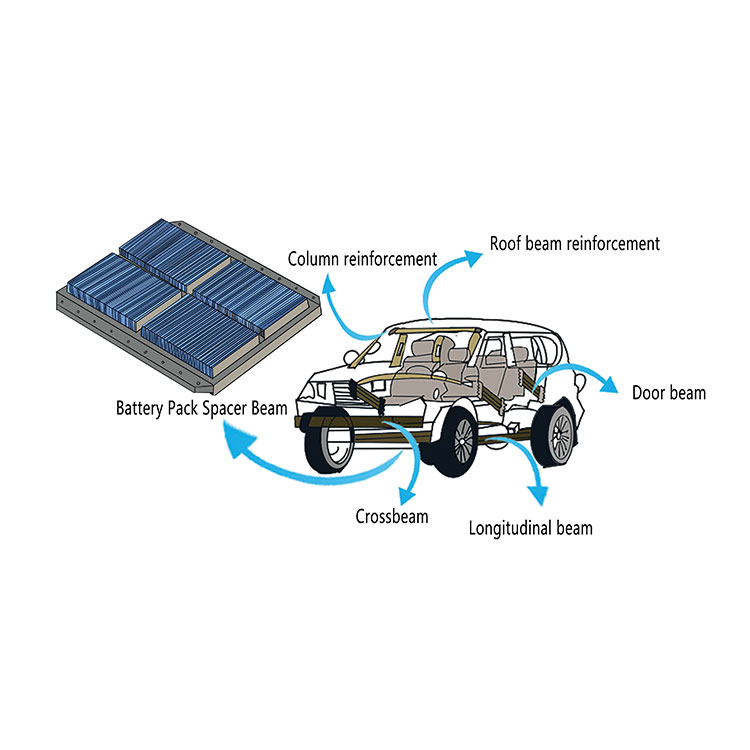

Vehicle Composite Profiles

Our FRP composites are at the forefront of enhancing the structural components of new energy vehicles. Our Vehicle Composite Profiles include key elements such as Column Reinforcements, Battery Pack Spacer Beams, Crossbeams, Roof Beam Reinforcements, Door Beams, and Longitudinal Beams. Designed for the next generation of vehicles, these profiles offer unmatched strength and durability, crucial for the rigorous demands of new energy vehicle architecture.FRP Pallets

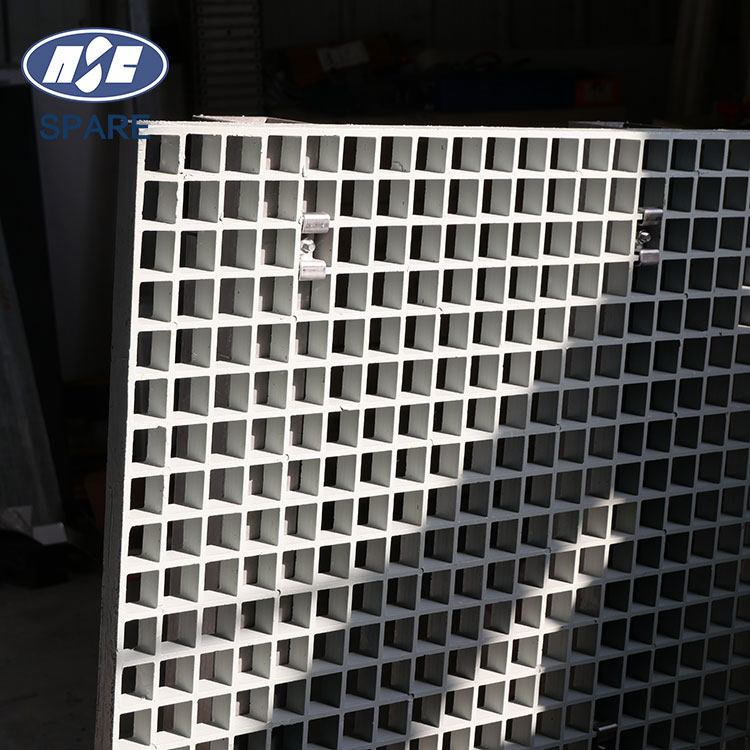

Our new FRP Pallets provide an innovative and sustainable alternative to traditional wooden pallets. Engineered from high-quality fiberglass reinforced polymer (FRP), these pallets are lightweight, durable, and resistant to corrosion and chemicals. Perfect for diverse industries, FRP pallets enhance efficiency and hygiene in your material handling operations.FRP Epoxy Pultruded Profiles

In transformer manufacturing, FRP Epoxy Pultruded Profiles are a key structural support element used to support and secure the coils and insulation system inside the transformer. They are made of high-strength fibre reinforced plastic (FRP) and have good mechanical properties and corrosion resistance, enabling stable long-term operation in harsh environments.FRP Toothed Tube

FRP Toothed Tube is a high-performance composite material tube that incorporates a specific toothed shape on its inner and outer surfaces to enhance structural rigidity and connection strength. This material combines lightweight, high strength, and corrosion resistance, making it suitable for use in automation machinery, automotive manufacturing, and construction engineering among other fields.Fiberglass Windows and Doors Profiles

Fiberglass Windows and Doors Profiles products are an innovative material made from fibreglass reinforced plastic (FRP) for the manufacture of high-performance, durable and aesthetically pleasing windows and door frames. They combine the strength of fibreglass with the durability of plastic, offering a completely new option for construction projects.FRP Upper Lip

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Upper Lip is customized product.