China Fiberglass Cable Support Manufacturer, Supplier, Factory

The client satisfaction is our primary concentrate on. We uphold a consistent level of professionalism, top quality, credibility and service for Fiberglass Cable Support,Ladder Shaped Fiberglass Cable Tray,Fiberglass Cable Tray,FRP Cable Tray,Fiberglass Bracket, To significantly improve our assistance quality, our company imports a large number of international advanced devices. Welcome clients from your home and abroad to simply call and inquire!

Fiberglass Cable Support, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to offer our clients sincerely with qualified solutions, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

Hot Products

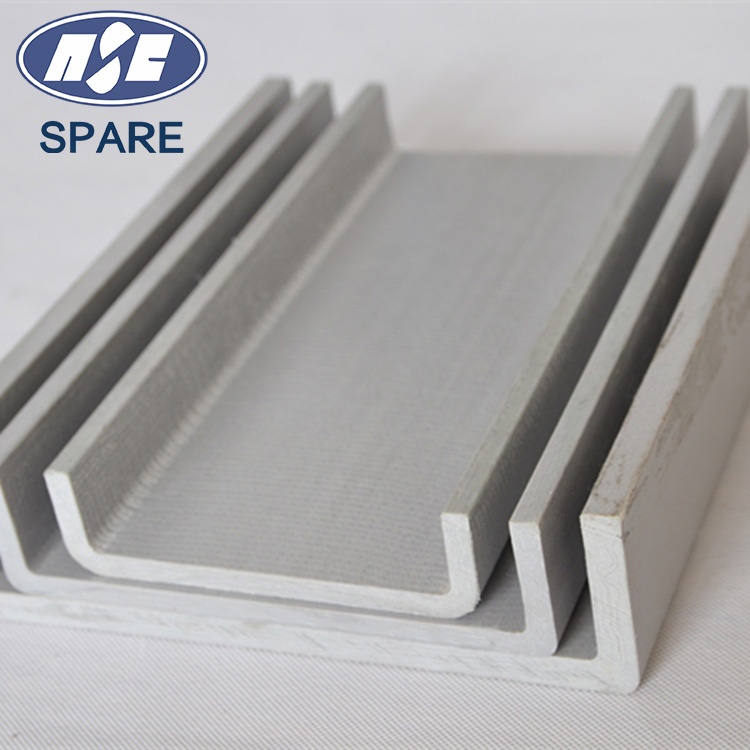

FRP Channel

FRP channel steel is a channel steel-like material composed of glass fiber and resin. It is corrosion-resistant, lightweight, and high-strength. FRP channel steel is usually used in industrial pipes, storage tanks, bridges, ships and other fields, and is widely used in chemical industry, environmental protection, shipbuilding, construction and other industries.Fiberglass Windows and Doors Profiles

Fiberglass Windows and Doors Profiles products are an innovative material made from fibreglass reinforced plastic (FRP) for the manufacture of high-performance, durable and aesthetically pleasing windows and door frames. They combine the strength of fibreglass with the durability of plastic, offering a completely new option for construction projects.FRP Toothed Tube

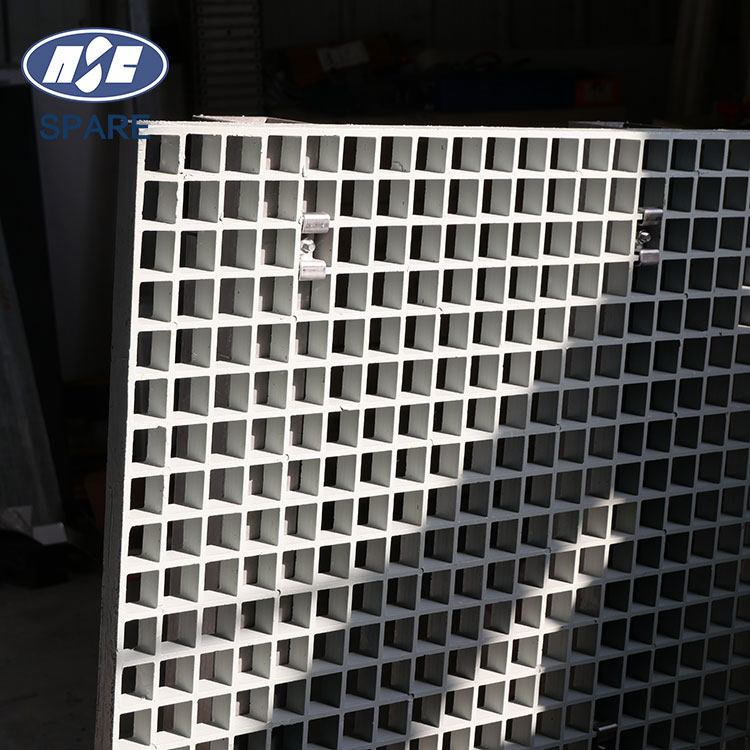

FRP Toothed Tube is a high-performance composite material tube that incorporates a specific toothed shape on its inner and outer surfaces to enhance structural rigidity and connection strength. This material combines lightweight, high strength, and corrosion resistance, making it suitable for use in automation machinery, automotive manufacturing, and construction engineering among other fields.Fiberglass Guardrail Handrail

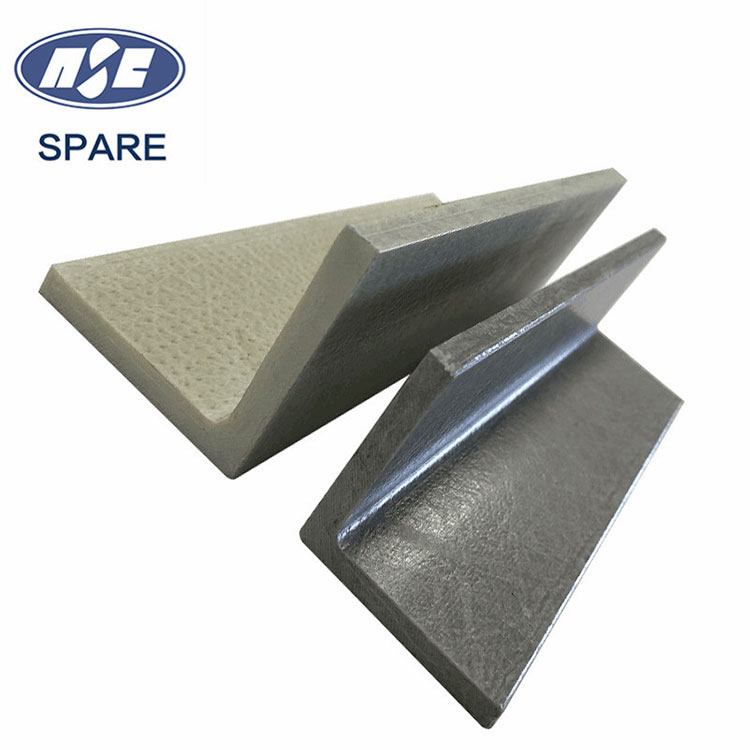

Fiberglass guardrail handrails are a kind of handrail material made of fiberglass and resin. They are often used in the design of guardrail handrails in stairs, corridors, balconies and other places.FRP Pultruded Flat Plate

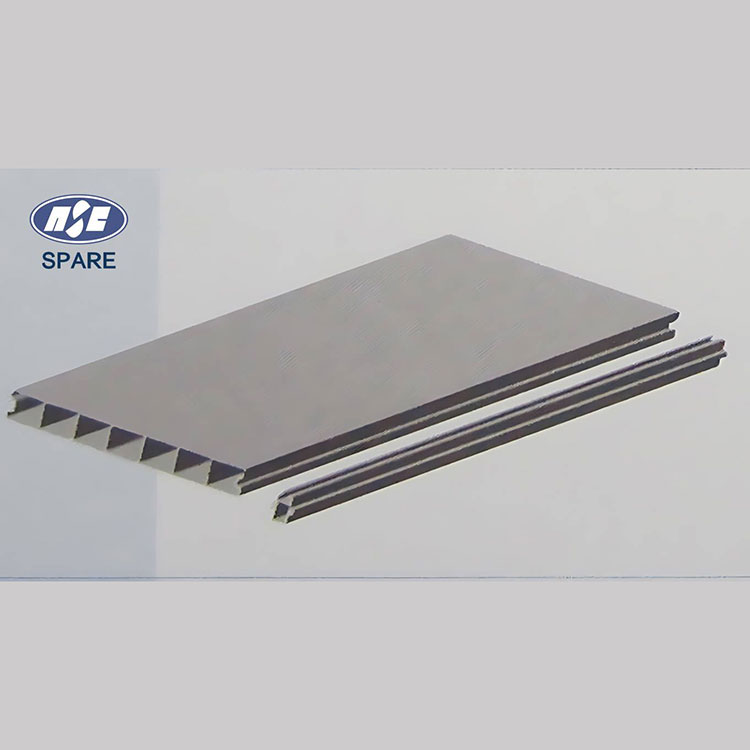

FRP pultruded flat plate is a flat plate material made of fiberglass and resin composite materials. It has the characteristics of light weight, high strength, corrosion resistance, insulation, etc., so it is widely used in many fields.FRP Handrail

Ideal for durability, safety and environmental protection

Our Fiberglass (Fibre Reinforced Plastic) handrails are well-designed, durable and reliable marine engineering solutions. Using advanced materials and processes, our FRP handrails offer outstanding performance and a variety of benefits.