China Fiberglass Cover Manufacturer, Supplier, Factory

We believe in: Innovation is our soul and spirit. Quality is our life. Shopper need is our God for Fiberglass Cover,FRP Cover,Fiberglass Cover Plate,GFRP Covers,GRP Covers, our products have good reputation from the world as its most competive price and our most advantage of after-sale service to the clients。

Fiberglass Cover, As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

Hot Products

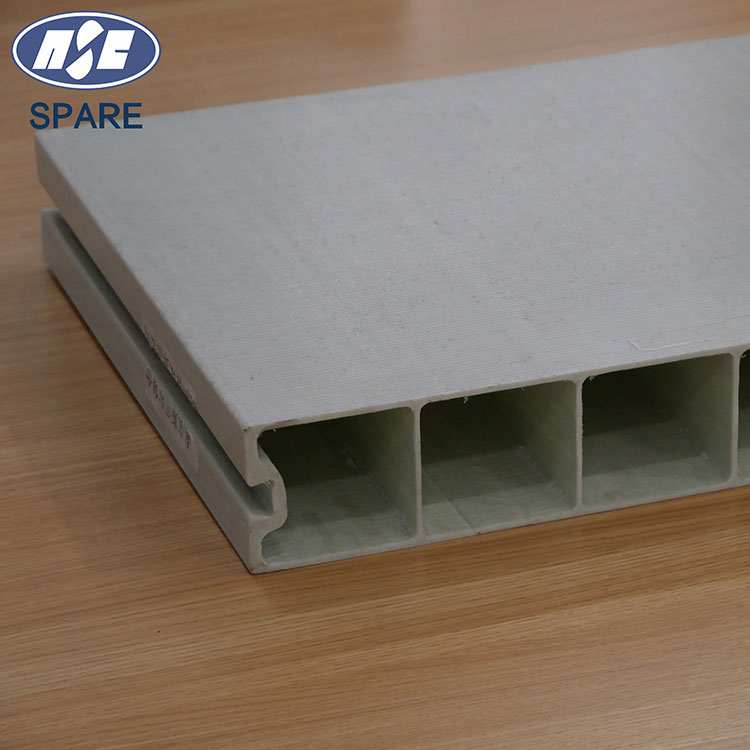

FRP Decking

Discover the outstanding durability and versatility of our FRP (Fiber Reinforced Polymer) Decking, specially engineered to meet the rigorous demands of industrial, commercial, and coastal environments. Our FRP Decking offers superior strength, corrosion resistance, and low maintenance, making it the ideal solution for a wide range of applications, including boardwalks, bridges, and building structures, especially in harsh conditions.FRP 50 Square Tube Accessories

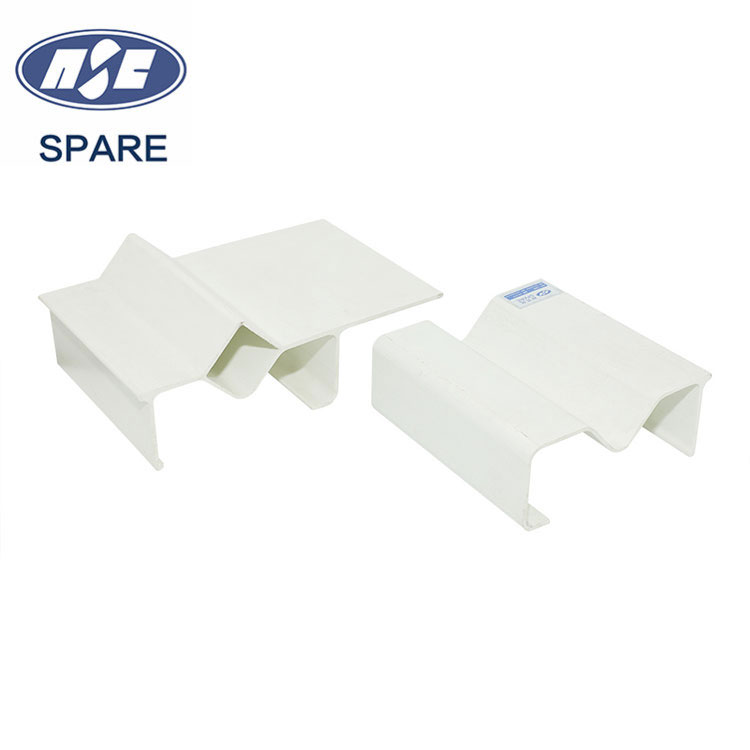

FRP 50 square tube accessories refer to accessories used to connect, fix and support FRP 50 square tubes, usually made of FRP materials.FRP Upper Lip

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Upper Lip is customized product.Fiberglass I-Beam

Fiberglass I-beam is a composite material composed of glass fiber and resin matrix, which has excellent mechanical and chemical properties. It is usually used in buildings, bridges, roads and other projects as reinforcement and structural materials. The use of fiberglass I-beams can effectively improve the wind resistance, earthquake resistance and durability of the structure, and is a very important building material.FRP Bowler Hat Profile

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Bowler Hat Profile is customized product.FRP D Profile

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP D Profile is customized product.