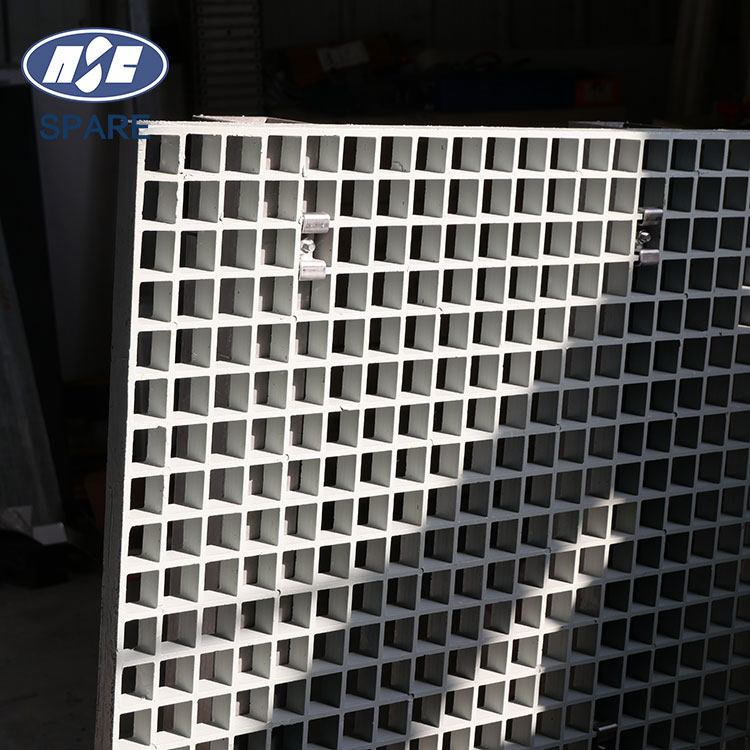

China Fiberglass Extruded Grille Manufacturer, Supplier, Factory

Our pursuit and company purpose is always to "Always satisfy our consumer requirements". We keep on to acquire and style and design remarkable high-quality products for each our outdated and new customers and reach a win-win prospect for our consumers as well as us for Fiberglass Extruded Grille,FRP Extruded Grille,Frp Grating,Squeezing Grille,FRP Grating, We feel that our warm and experienced company will bring you pleasant surprises as perfectly as fortune.

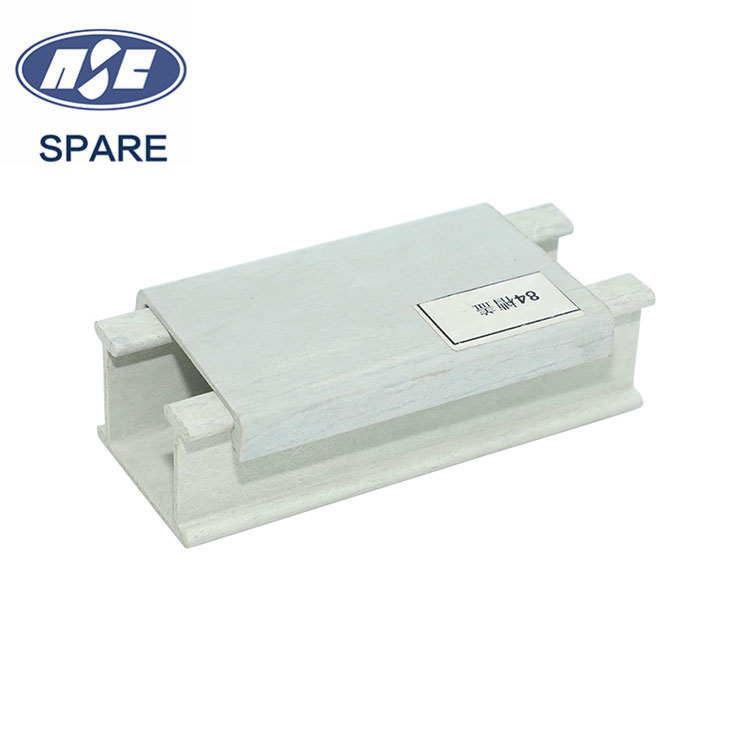

Fiberglass Extruded Grille, Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve products and provide more comprehensive services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

Hot Products

FRP Round Pipe Accessories

FRP round pipe accessories refer to accessories used to connect, fix and support FRP round pipes, usually made of FRP materials.FRP Rectangular Tube

Engineered from durable fiberglass, this FRP rectangular tube offers high strength and corrosion resistance. Ideal for applications requiring structural integrity and versatility in diverse environments.FRP Fence

FRP (Fiber Reinforced Polymer) Fence is a high-performance, corrosion-resistant fencing solution tailored for outdoor environments. Built for durability and easy installation, it's ideal for residential yards, scenic locations, and industrial sites. Made from premium FRP profiles, this FRP fence offers long-lasting protection with minimal maintenance, providing an efficient, cost-effective alternative to traditional fencing.Triple-Glazed PU Woodgrain Window

Triple-Glazed PU Woodgrain Windows combine the strength of polyurethane composite with the timeless beauty of wood. Featuring a triple-glazed system for superior energy efficiency and a PVC wood grain finish, these windows offer the durability of fiberglass with the elegance of natural wood. Lightweight, weather-resistant, and maintenance-free, they are perfect for both residential and commercial applications, offering lasting performance and style.FRP Pallets

Our new FRP Pallets provide an innovative and sustainable alternative to traditional wooden pallets. Engineered from high-quality fiberglass reinforced polymer (FRP), these pallets are lightweight, durable, and resistant to corrosion and chemicals. Perfect for diverse industries, FRP pallets enhance efficiency and hygiene in your material handling operations.FRP D Profile

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP D Profile is customized product.