China Structual Building Panel Manufacturer, Supplier, Factory

Our corporation has been specializing in brand strategy. Customers' gratification is our greatest advertising. We also source OEM company for Structual Building Panel,Round Rod,Flat Strip,C-Channel,Decking, And there are quite a few international friends who came for sight seeing, or entrust us to buy other stuff for them. You might be most welcome to arrive to China, to our city also to our factory!

Structual Building Panel, Adhering to the principle of "Enterprising and Truth-Seeking, Preciseness and Unity", with technology as the core, our company continues to innovate, dedicated to providing you with the highest cost-effective solutions and meticulous after-sales service. We firmly believe that: we're outstanding as we have been specialized.

Hot Products

T-Type Fiberglass Pultruded Grating

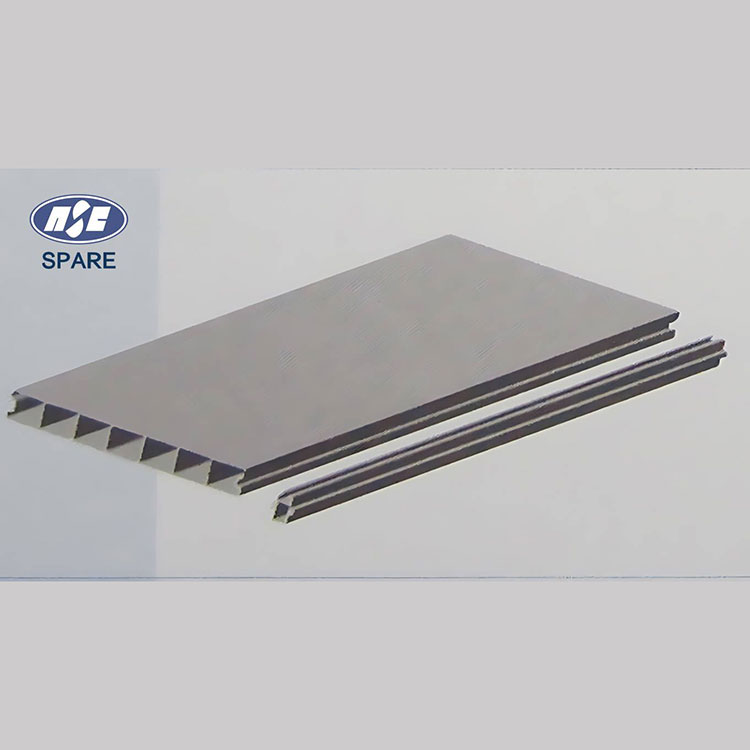

T-Type Fiberglass Pultruded Grating is a plate with gaps made by using pultruded "I" and "T" shaped profiles as load-bearing bars, solid pipes or rods as connecting rods, and a certain assembly process.Hollow Decking

Our FRP Hollow Decking, made from Fiber Reinforced Polymer (FRP), was successfully used on Thailand's Rama VIII Bridge. These GFRP pultruded hollow web panels reduce wind resistance, lower maintenance costs, and enhance aesthetic appeal. Installed after rigorous field loading tests, our decking offers superior quality and reliability for any project.Fiber-reinforced Composite Rebar

Fiber-reinforced composite rebar is a kind of composite material made of polymer resin as the matrix and glass fiber, basalt fiber or carbon fiber as the reinforcement.FRP Upper Lip

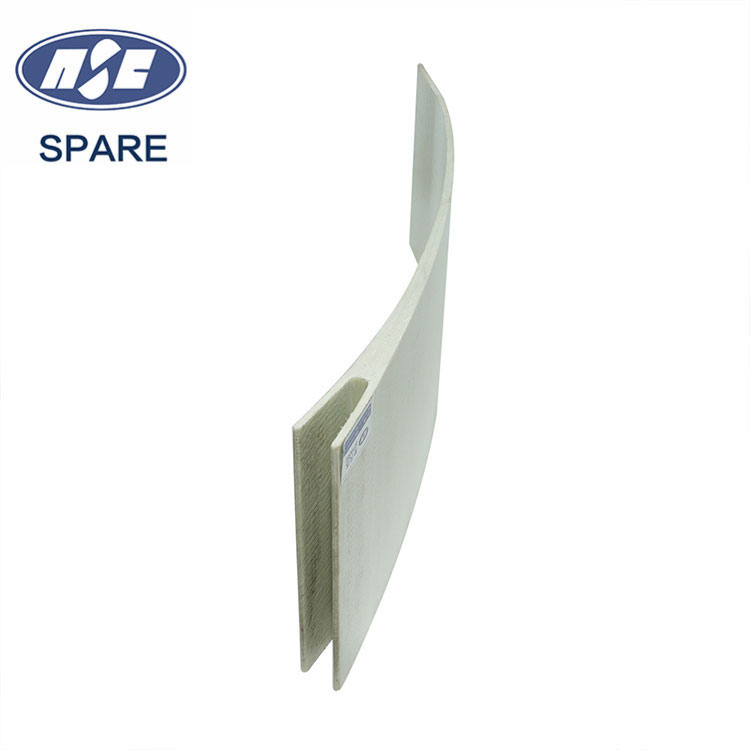

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Upper Lip is customized product.FRP Wiind Turbine Tail

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Wiind Turbine Tail is customized product.FRP Corrugated Board

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Corrugated Board is customized product.