China Fiberglass Joints Manufacturer, Supplier, Factory

We know that we only thrive if we can easily guarantee our combined cost competiveness and high-quality advantageous at the same time for Fiberglass Joints,Fiberglass Connectors,Fiberglass Link Accessories,Fiberglass Turning Joint,Fiberglass Fasteners, We sincerely be expecting exchange and cooperation with you. Allow us to move forward hand in hand and accomplish win-win circumstance.

Fiberglass Joints, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products for our customers.

Hot Products

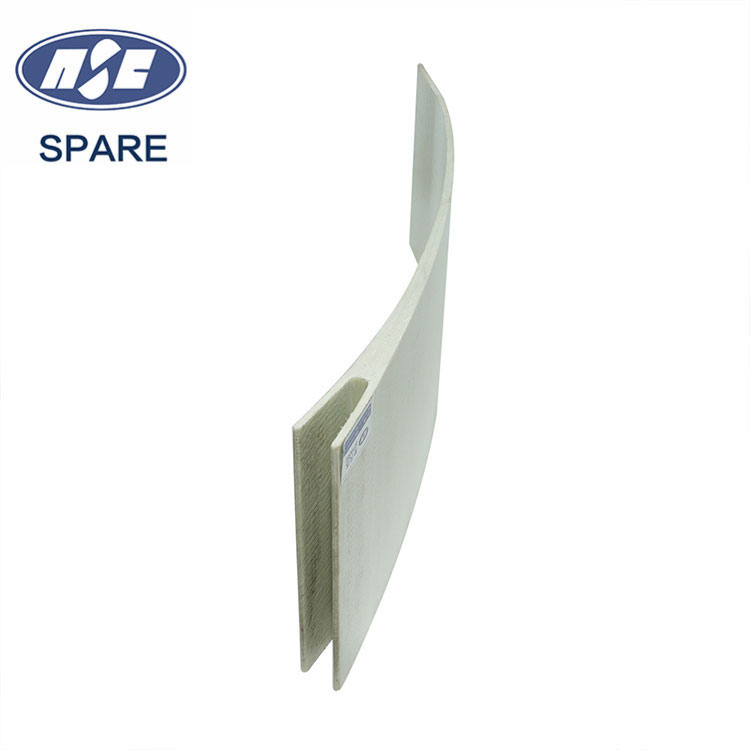

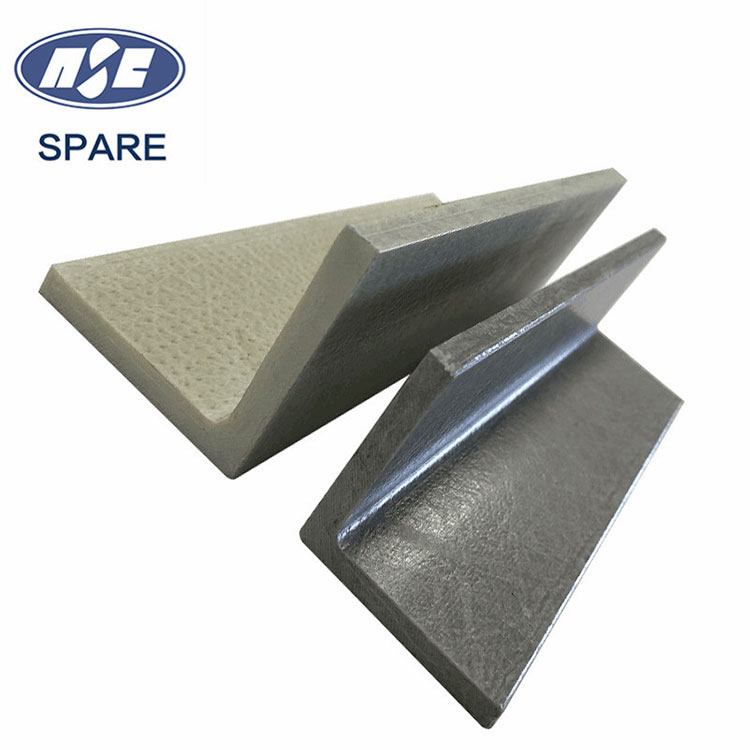

Fiberglass Angle

Fiberglass Angle is a structural material made from glass fibre reinforced plastic. It has excellent strength and corrosion resistance and is suitable for a wide variety of applications including construction, shipbuilding, chemicals and more. Due to its light weight and weather resistance, Fiberglass Angle offers significant advantages when replacing traditional materials.FRP Wind Panel

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Wind Panel is customized product.FRP Wood Grain Profile

FRP Wood Grain Profiles combine fiberglass-reinforced plastic (FRP) with a wood-like finish, offering the look of natural wood with the durability and low maintenance of FRP. Ideal for both residential and commercial use, they mimic the textures and colors of real wood, making them perfect for exterior cladding, furniture, and decorative trim.FRP Handrail

Ideal for durability, safety and environmental protection

Our Fiberglass (Fibre Reinforced Plastic) handrails are well-designed, durable and reliable marine engineering solutions. Using advanced materials and processes, our FRP handrails offer outstanding performance and a variety of benefits.FRP Fence

FRP (Fiber Reinforced Polymer) Fence is a high-performance, corrosion-resistant fencing solution tailored for outdoor environments. Built for durability and easy installation, it's ideal for residential yards, scenic locations, and industrial sites. Made from premium FRP profiles, this FRP fence offers long-lasting protection with minimal maintenance, providing an efficient, cost-effective alternative to traditional fencing.Fiberglass Guardrail Handrail

Fiberglass guardrail handrails are a kind of handrail material made of fiberglass and resin. They are often used in the design of guardrail handrails in stairs, corridors, balconies and other places.