China FRP Rod Manufacturer, Supplier, Factory

We've got a remarkably efficient crew to deal with inquiries from clients. Our aim is "100% purchaser satisfaction by our item high-quality, selling price & our crew service" and appreciate an excellent popularity amid consumers. With quite a few factories, we could present a wide variety of FRP Rod,Fiberglass Support Rod,Fiberglass Pole,Fiberglass Bracket,Fiberglass Round Rod, As an experienced group we also accept tailored orders. The main aim of our corporation is always to develop a satisfying memory for all shoppers, and set up a long-term win-win business partnership.

FRP Rod, We believe in establishing healthy customer relationships and positive interaction for business. Close cooperation with our customers has helped us to create strong supply chains and reap benefits. Our products have gained us widespread acceptance and the satisfaction of our worldwide valued clients.

Hot Products

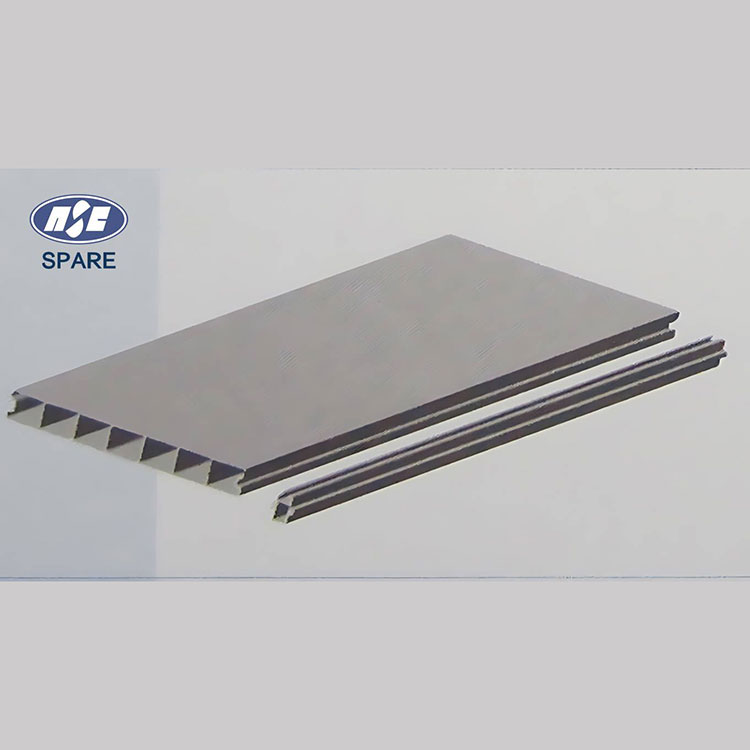

Hollow Decking

Our FRP Hollow Decking, made from Fiber Reinforced Polymer (FRP), was successfully used on Thailand's Rama VIII Bridge. These GFRP pultruded hollow web panels reduce wind resistance, lower maintenance costs, and enhance aesthetic appeal. Installed after rigorous field loading tests, our decking offers superior quality and reliability for any project.Fiberglass Guardrail Handrail

Fiberglass guardrail handrails are a kind of handrail material made of fiberglass and resin. They are often used in the design of guardrail handrails in stairs, corridors, balconies and other places.Military Temporary Housing

To address urgent lodging needs in extreme conditions, our Military Temporary Housing utilizes advanced Fiber Reinforced Polymer (FRP) technology. This innovative construction offers a lightweight yet durable lodging option, ensuring rapid deployment and exceptional resilience. The unique properties of FRP make it an ideal choice for temporary or emergency situations, providing robust shelter solutions when and where they are needed most.FRP Bridge Elbow

The FRP bridge elbow is a special-shaped FRP bridge component used to connect two straight sections of bridge and change the direction.GFRP Handle Tube

Pultruded GFRP round tubes are designed for tool handle applications requiring high strength, light weight, and corrosion resistance. Made from continuous glass fiber and thermosetting resin, these tubes offer excellent durability and electrical insulation, ideal for gardening, cleaning, and industrial hand tools.Ladder Type Fiberglass Bridge

Ladder type fiberglass bridge is a special form of FRP bridge with a trapezoidal or stepped structure. It is usually used in situations where cables need to span different heights or need to be routed along slopes.